The angle grinder arbor size is one of the important factors to consider when choosing an ideal tool for your tasks. Since this part is the connecting point between your grinder and the grinding wheel, it affects both your machine’s performance and attachment availability.

This article will focus on the importance of the arbor size, and other factors contributing to selecting an appropriate angle grinder.

Contents

What Is An Arbor On An Angle Grinder?

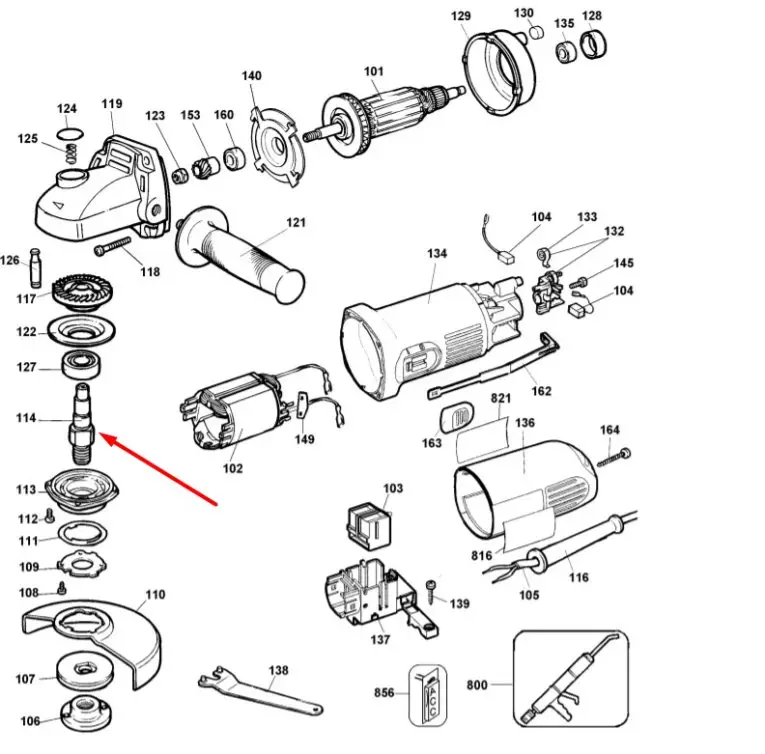

The angle grinder arbor, which is commonly knowns as spindle, is the shaft that protrudes at a perpendicular angle to the grinder’s end. This is the component to which the grinding/cutting wheel is attached. It is powered by the grinder’s drive motor and threaded at the outboard end.

Some abrasive discs just simply drop on the arbor, then, during use, they are securely held in place by a special screwed nut. In some instances, this nut has 2 flanges allowing it to fit from ⅝ to ⅞-inch holes in the wheel. Other wheels have their threads which are screwed onto the spindle’s threads.

It’s worth noting that the disc hole’s diameter, pitch (number of threads for every inch), and thread size must all match the arbor.

Standard Angle Grinder Arbor Size

Arbor size is one of the most important factors to choose the right angle grinder for your job. With American-made angle grinders, the standard size of arbor is ⅝-11, which means its diameter is ⅝ inches and there are 11 threads every inch.

A few grinders employ metric threads, like M10 or M14, but they’re quite uncommon. Some smaller angle grinders as well as a majority of pneumatic models use ⅜”-24 spindle (⅜ inch for the diameter and 24 threads per inch).

It may appear perplexing, however, there are rules of thumb to clear up your confusion. When a disc’s hole is ⅞ inches in diameter, it’ll fit on almost non-pneumatic angle grinders as long as the nut is used to secure the wheel to the machine’s shoulder.

While most grinders will accept a ⅝-inch wheel bore because they are usually threaded on the spindle.

How to adapt smaller spindles?

America imports many angle grinders and these imported machines often have smaller spindles in terms of diameter which is also measured in the metric system.

In many cases, grinding discs that have a ⅝” hole can still work on angle grinders with smaller spindles thanks to the machine’s flanges and lock nuts. The features help center the grinding wheels, so attaching these wheels to your small-arbor grinder shouldn’t be an issue.

However, there are instances when this combination isn’t possible. So, you should use an angle grinder spindle adapter in these cases. Commercial arbor adapters are affordable, ranging from around $4 to $10.

You will attach an adapter to the grinder arbor to change its thread size. This enables your power tool with a smaller arbor to utilize a wider range of discs and abrasives, which improves its versatility. Another common usage of the spindle adapters is to use grinding discs with inch and metric threads interchangeably.

Factors To Consider When Choosing An Angle Grinder

Besides the arbor size, some other factors to consider when selecting an angle grinder include its power source, motor power, disc size, and RPM, etc., among which the wheel size and the power of the motor are the most crucial ones.

Power of the motor

For this criterion, you should check the grinder’s wattage. The higher the wattage, the more power your tool can generate during cutting or grinding jobs. You’ll need higher watts if you own a grinder with a larger cutting wheel.

Also, look at the power tool’s amps, as a higher number can indicate the grinder’s capability to handle heavy-duty tasks.

Cutting disc size

The cutting disc size can range between 4 and 9 inches. The rule of thumb is the larger the disk, the more powerful the motor is required.

However, a larger wheel isn’t usually needed. For instance, if smoothing a material or another tool’s cutting edges, you’ll need a lot of precision. Then, a smaller wheel size will be ideal. So, always select the appropriate disk size for your work project.

Power mode

There are 3 main power modes for angle grinders: electrical, pneumatic, and petrol grinders. Each of these types has its own set of advantages and disadvantages.

The first group – the electric one, is usually powered by a direct source of electricity or a battery. They cannot run if their battery runs out or there is a power cut, while the petrol grinders need to be refueled to continue working.

The battery-powered grinders are lightweight and portable, allowing you to work wherever you like. Therefore, you should always weigh the benefits and drawbacks of those 3 types before deciding which one to purchase for your job.

Speed

The standard RPM of an angle grinder is between 700 and 1,200. The higher the grinding wheel’s RPM (revolution per minute), the higher effectiveness you can get from the power tool.

The high-speed angle grinders can reach between 5,000 and 10,000 RPM, making them more ideal for various projects. When you have metal cutting or grinding projects, pick the one with a relatively higher speed. As for lighter tasks like wood or brick cutting, you can pick those with lower RPM.

Related Questions

1. Should I choose a small or large angle grinder?

The answer depends on the type of project that you are carrying out.

Small angle grinders

The small grinders normally handle wheels of up to 7 inches, with the most popular one is 4 – 4 ½ and smaller models able to handle 3-inch discs. They can be used for various cutting and grinding projects.

Small grinders should ideally feature a brushless motor, which eliminates the need to change brushes regularly. This feature also enables the cordless models to operate efficiently, reducing the heat build-up and extending the tool’s life.

Also, they should be equipped with a kickback brake, a crucial safety element to ensure that the disc stops immediately if it becomes stuck. This will keep the grinder from falling freely and causing severe damage.

Some small angle grinders also have 2-stage triggers, which require the safety switch to be turned off before the tool can be activated by the trigger. This reduces the possibility of unintentional starts when you change the discs.

Medium to large angle grinders

Grinders that have 7-inch wheels are classified as medium, whereas those that have from 7-inch to 9-inch wheels are classified as large. The large grinders are designed specifically for making large cuts and scanning large areas in 1 pass.

Moreover, they have a significant amount of horsepower. Medium-to-large grinders are frequently corded. High-quality medium grinders have a minimum of 3 HP, while the large counterparts have more than 5 HP.

Before buying, keep in mind that overload protection is a typical feature that large grinders should have. This characteristic prevents the machine from breaking down due to heavy weight.

Also, look for the one that is automatically shut off if the tool is suddenly dropped, which is to protect the grinder’s motor.

Some models have movable side handles, providing the power tools with more flexibility and maneuverability. There may also be an option of installing a vacuum attachment to effectively collect dust and debris generated by the grinder while in use.

2. Are all angle grinders the same size?

No, they come in many different sizes, ranging from small to medium & large.

3. What are popular angle grinder brands?

Some reputable names on the angle grinder market are DeWalt, Makita, Metabo, Bosch, Milwaukee, and so on.

Final Words

Being aware of your angle grinder arbor size will help you identify suitable grinding/cutting discs for your power tool, which in turn will guarantee its effectiveness and long life. However, due to the availability of arbor adapters, the spindle size is not a deciding factor when you purchase a new grinder.

As a result, you should prioritize other factors (especially the cutting disc size and the motor power) and angle grinder types to select the best tool for your tasks.

thanks for your helpful site ! I need anarbor adapter from the smaller size to the 5/8th could you ship that to me ?

sorry we don’t buy anything.