All angle grinder discs aren’t the same and each of them serves different purposes. Therefore, if you just purchase a quality angle grinder and want to increase the efficiency and productivity of your angle grinder, read our article below about 10 different types of angle grinder discs and their specific uses.

10 Types Of Angle Grinder Discs

1. Grinding Disc (Grit Disc)

Grinding discs can be considered the most universal angle grinder wheels. Grit discs, an alternative name for grinding discs, are available in several shapes and sizes.

Grit is a unit of measurement for the hardness as well as smoothness of grinding wheels. The higher number of grit, the less coarse your grinding disc is, which is similar to sandpapers.

Low-grit grinding wheels remove materials more quickly, however, they generate more sparks and have a rougher appearance. The low-grit grinding discs can also cause minor burns and more scratches than their high-grit counterparts.

Usages

In general, grinding discs are commonly used to grind, remove superfluous material from a surface, prepare metal material for welding and clean up cuts. Other usages include sharpening gardening tools such as shovels and grinding out metal welds.

2. Cut-off Disc

Cut-off discs are the second most popular cutting disc type of angle grinder wheels. They are narrower than grinding discs to give the most precise cuts. As a result, dealing with them is riskier.

This type of angle grinding disc can readily be shattered if they are used in a position in which they are bent or the position of your angle grinder is suddenly changed.

Cut-off discs’ shattered flying fragments are dangerous and can cause serious injuries. So, when using an angle grinder, you should wear high-quality safety equipment.

Usages

The cut-off wheels are utilized to cut off metal bars and metal sheets as well as small workpieces of metal sheets and plates. It’s obvious that this is an angle grinder disc type for steel. Other usages of cut-off discs include cutting out welds and shortening bolts’ length.

3. Flap Disc

Flap wheels and grinding discs have a lot in common. Flap discs are also available in several grits. However, flap discs are smoother.

Usages

They are mostly utilized for finishing jobs like smoothing extensively ground surfaces, removing burrs and scrapes. Other usages include chamfering, removing sharp edges, and shining up gouged metal.

4. Wire Brush Wheel

Wire brush discs are made out of a circle-shaped base and a bundle of wires. Like other discs for angle grinders, wire discs come in a variety of forms and sizes to accommodate many applications.

Wire wheels with thick, twisted bristles are regarded as more abrasive and can do tasks faster and more easily. By contrast, thinner, straighter bristles are regarded as less forceful and utilized for finer work.

Usages

If removing rust from workpieces is your purpose, one of the quickest and easiest ways to get a clean surface is using a wire brush wheel. You can also use this type of disc to remove paint off surfaces.

5. Diamond Cutting Disc

Diamon cutting wheels are unquestionably the sharpest angle grinder discs. Diamonds are embedded in the surface of these discs’ edges. They usually feature a cutting rim on which the cutting procedure is carried out. The higher their cutting rim, the sturdier and more long-lasting they will be.

Usages

Due to the diamond edges, these wheels are ideal for cutting refractory and difficult-to-penetrate materials such as all varieties of granite. They can also be used to cut both dry and wet materials.

6. Strip Disc (Paint Stripping Disc)

Besides a wire disc, you can also use a paint stripping wheel. This alternative option may be more appropriate if you’re working on soft metal, wood, or fiberglass which you don’t want to scratch with a wire disc.

Usages

Unlike wire discs with wire bristles, strip discs have poly-fiber material, which effectively removes paint without scratching or scuffing the underlying surface. The paint stripping wheels can also be used to clean off epoxy or other contaminants.

7. Polishing Pads

Like other angle grinder attachments, polishing pads are available in a variety of shapes and materials, each of which can offer a unique and shiny final look to your workpieces.

Because polishing necessitates a specified speed, your angle grinder should have a speed control feature to utilize polishing pads.

8. Concrete Grinding Wheels

These discs are suitable for polishing or grinding concrete in addition to metal. Concrete grinding discs come in a variety of forms and grit materials including diamond grit wheels and silicon carbide grain wheels.

Those with a diamond cup are the most popular since they can be utilized on a wide range of materials and are long-lasting.

The concrete grinding discs are comprised of solid materials, including durable fiberglass and other hard abrasive materials. These components both facilitate the discs to last longer and assist them to push through concrete.

Usages

In addition to concrete, you can use them to grind masonry, granite, marble, marble, stone, and other similar hard materials. Even though concrete grinding discs are durable, they will ultimately wear out. When in use, old wheels are more likely to chip.

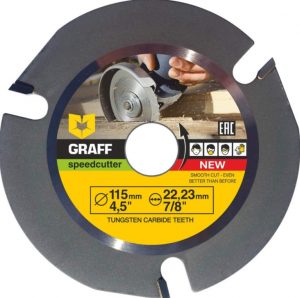

9. Wood Cutting Discs

Only a handful of angle grinder discs are suitable for projects with tougher materials. If you try to cut, carved wood with grinder discs used for metal, you may wind up ruining your craft. That’s why there are angle grinder disc types for wood.

A toothed and circular blade is a common feature of wood cutting wheels. Their tips are frequently made of tungsten carbide. Since this material is extremely durable, manufacturers use it as a wood-cutting discs’ tip.

Usages

Since carbide teeth are very strong, they can make cuts on both softwood and hardwood with ease. A good cutting wheel should slice through mahogany, pine, maple, cherry, or other types of wood you can think of with ease.

Moreover, you can use these teeth for a long time before sharpening or replacing new blade.

10. Wood Carving Discs

Similar to woodcutting discs, carbide teeth are also commonly included in the wood carving discs.

However, wood carving wheels are donut-shaped instead of being flat. The teeth aren’t around their edges but instead, cover their whole surface. There are typically hundreds of teeth on each wood carving disc.

Usages

The disc’s form makes it particularly well suited to forming a concave surface such as the inside of wooden bowls.

Notices

Remember that dealing with wood differs from working with metal and concrete. Typically, these materials are homogeneous, while natural curves and knots are found in wood. When using wood carving/cutting wheels, it is important that you choose an angle grinder specifically for wood carving!

Always Use Angle Grinders With Care!

Angle grinders include two potentially dangerous components: a fast-spinning engine and a sharp cutting wheel. To avoid major injuries, always keep the following safety precautions in mind:

- Before plugging in your angle grinder, make sure that it is turned off.

- Read the handbook to learn how to use your angle grinder correctly.

- Make sure you’re using the correct grinding wheel for the task at hand.

- Wear the appropriate clothing and protective gear.

- Use your angle grinder correctly (e.g.: keep its safety guard on, use the device with both hands, inspect it before starting a job, etc.)

- Maintain your concentration.

Before Leaving

It’s worth noticing that angle grinder discs are interchangeable. You can choose the right size and the suitable type of wheel for the material you are cutting or grinding.

And, there are various types of angle grinder discs that you can choose for a specific angle grinder. Whatever type you will be using, always work with care to avoid injuries.

Awesome!!