Angle grinders are power tools that can be used to cut through various materials, including solid ones like aluminium.

If you are uncertain about cutting aluminium with angle grinders, our guide will help you choose the best cutting disc for the job and do it safely and efficiently.

Contents

Cutting Aluminium With Angle Grinders: Is It Possible?

You can cut aluminium and other hard materials such as bricks, steel… with a suitable angle grinder. However, a suitable cutting disc is required, and you have to choose the correct approach to handle the job smoothly without any accident.

Don’t worry. All of the questions that you may have will be covered in our next sections.

How To Cut Aluminium With An Angle Grinder?

Step 1. Set up your angle grinder

Set up your power tool after getting everything prepared and put on all safety equipment.

Ensure that your grinder is turned off and disconnected from all power sources. After that, place the metal wheel in your grinder. Ascertain that the metal blade and other attachments are securely attached and fitting.

Step 2. Mark the area

You’ll then outline the metal area you’ll be cutting to increase precision. Place the aluminium workpiece on your workbench and fix it securely with clamps to prevent it from moving.

Then, carefully outline the workpiece to match the design you wish to accomplish.

Mark both ends of the line and cut accordingly to obtain a straight line. Extend each of your cuts marginally beyond the indicated line to ensure that the aluminium workpiece’s corners are properly cut.

For more difficult designs like curves or zigzags, use an awl to etch stretch points before outlining the entire pattern.

Step 3. Start cutting

Now that the preliminary work, such as outlining, has been accomplished, it’s time to begin cutting aluminium.

Plug your angle grinder in a power source and turn it on. Before turning it on, make sure that you have a strong grip on it, since its strength and vibration may cause you to be stunned, especially if you are a newbie.

Gradually cut your marked outline with the blade rotating.

Step 4. Be consistent while cutting

This essentially means that when cutting, you shouldn’t shift the direction of your grinder haphazardly. Changing directions while cutting might result in a variety of issues. For instance, your cuts may not be precise, or worse, they could go off the marked line.

There may be instances when you feel that the grind is slowing down. When this happens, do not stop cutting. Instead, continue in one way, to and fro, along the specified line.

Step 5. Finish the cut

After you have successfully cut the aluminium workpiece to your specifications, be sure not to touch its sharp edges that result from the cutting process.

Use a 40-grit flapper to replace the wheel after turning off your angle grinder and unplugging the tool from the power outlet.

Then, plug it in again and turn it on. Next, move the grinder along the sharp edges of the aluminium workpiece to gradually smoothen them. After checking that these edges are smooth enough, your job is done.

Best Cutting Disc For Aluminium

By choosing the best cutting wheel for aluminium or metal, you can obtain better end products, including both thick aluminium and aluminium sheets, while ensuring greater safety and productivity. Moreover, it can also help you reduce downtime and save labor costs.

Below are some recommended options that you should consider for aluminium-cutting jobs.

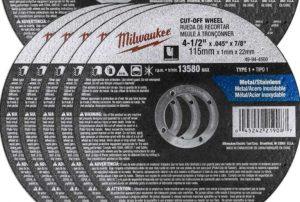

1. Metal cutting disc (or Cut-off disc)

This type of wheel can be used to cut most metals. Nevertheless, you must not use it for grinding. When in use, the cut-off disc should be perpendicular to your workpiece.

Aluminium Oxide is used to make the cutting edge. This material is well-known for its strength and durability, which can ensure your angle grinder’s effectiveness and productivity.

It also has a longer life span, compared to other media. This allows you to reuse it multiple times without losing effectiveness. As a result of the lower frequency of replacement, cutting wheels with an Aluminium Oxide edge provides exceptional value for money.

2. Grinding disc

Grinding wheels can be used to grind through both ferrous & non-ferrous metals. When in use, you should present a grinding disc at a 45-degree angle to your workpiece.

Similar to cut-off discs, grinding wheels’ cutting edge is also made from Aluminium Oxide. Thus, they share the same benefits from their cutting edge.

3. Multi-cut cutting wheel

The multi-cut cutting discs can also cut through both ferrous and non-ferrous metals. They can also be utilized in more complicated jobs such as cutting tiles, brick, modern composites, and stone.

4. Diamond all-cut blade

This type of wheel can cut through ferrous, non-ferrous metals, and cast iron, as well as a majority of construction materials due to the diamond grains embedded on the cutting edge.

Since diamond is even tougher than Aluminium Oxide, diamond all-cut discs can do whatever their Aluminium Oxide blades can and more.

5. Slitting disc (or thin cutting disc)

Generally, slitting wheels can be used to cut ferrous, non-ferrous metals, and stainless steel. They offer you fine cut lines.

Regarding benefits, the thin cutting blades produce less heat when in use, cause less tool vibration, finish cuts faster. Moreover, they waste less material per cut, saving a maximum of 2 millimeters per cut.

Some Safety Tips

The discs spin at a high rate, resulting in hot sparks and chips blasting off at high speeds. To stay safe, you should wear earplugs, heavy-duty work gloves, eye protection, and protective footwear.

Remember to pick the wheel most suitable for your job. Ensure that the wheel’s maximum RPM is faster than the grinder’s maxim RPM, which will prevent the wheel from becoming over-stressed and fracturing. This can result in severe injuries.

Final Words

We hope that our step-by-step guide can help you cut aluminium with your angle grinder. With affordable equipment, you can cut and smooth aluminium efficiently. Remember to follow our tips about choosing the best cutting disc and safety to carry out your job effectively and safely.