An angle grinder is a versatile tool that can cut, polish, grind, sharpen, or smoothen various materials. But do you know that this handheld tool can do more than that with appropriate attachments?

Below are some most popular angle grinder attachments you should know about when using this tool for work.

Contents

6 Common Angle Grinder Attachments Everyone Should Have

1. Diamond cutting blade

A diamond cutting blade consists of a hardened steel core embedded with many abrasive diamond grains to cut or grind through hard materials with high power and precision.

There are many types of diamond blades, but the 3 most popular ones are:

- Continuous rim blade: This blade can perform smooth cuts on marble, porcelain, and ceramic tiles.

- Segment rim blade: This general-purpose blade can be used to cut or polish masonry, terrazzo, concrete, and roof tiles.

- Turbo rim blade: Thanks to its high speed and clear-cutting, this blade can work on slate, granite, concrete pipes, paver bricks.

2. Wire brush

Wire brush, available in many shapes, forms, and sizes is used in heavy-duty cleaning, edge blending, removing paint, and deburring.

There are 3 types of wire brushes:

- Knotted wheel brush: Its knotted design provides maximum aggressiveness and precision to the metal wires. This brush can prepare and condition rough surfaces on hard materials like stainless steel or iron.

- Crimped cup brush: A crimped cup brush is less aggressive but can cover larger and broader areas than a knotted wheel one. It has flexible wires, allowing it to create a uniform, smooth, and polished finish.

- Knotted cup brush: This type has the cup design of a crimped cup brush and the aggressive knotted wires of a knotted wheel brush. In other words, it can perform heavy-duty cleaning and conditioning on large surfaces (like removing rust and oxidation).

3. Sanding disc

A sanding disc is among the essential angle grinder attachments. It is a round disc with abrasive materials. This attachment is often seen in woodworking, and it is used for leveling wooden surfaces, sharping, carving, and smoothing hardwoods. Besides, you can use it on metalwork to remove scratches and rust off metal surfaces.

You can classify sanding discs by their abrasive materials and sanding discs.

Types of sanding discs

There are 2 types of sanding discs:

- Flap disc: A flap disc consists of many separated flaps made of sanding materials. This sanding disc can effectively sand and grind hard materials while lessening load and friction. Its flap design helps dissipate heat, thus lengthening the life of the abrasive grains and avoiding damages and overheating to the working surface. You can use a flap sanding disc on hardwood, cast iron, stainless steel, titanium.

- Ceramic disc: Although a ceramic sanding disc has a higher price tag than a zirconia disc or an aluminum disc, it can last longer and provide consistent, clean cuts. Its high abrasiveness makes it suitable for heat-sensitive materials like titanium, nickel alloy, and stainless steel.

Types of abrasive materials

There are 3 types of abrasive materials:

- Aluminum oxide: This abrasive material contains iron, making it ideal for sanding and polishing alloy steel, bronze, fiberglass, wood. But you should not use it on stainless steel since the iron composition can cause light oxidation.

- Zirconia: This iron-free abrasive material is stronger and lasts 10 times longer than aluminum oxide. It can effectively sand and polish fiberglass, wood, brass, metal, aluminum, and stainless steel. You can use a zirconia sanding disc to clean metal welds, remove old paints and contaminants, grind metal, and smoothen rough wood surfaces.

- Ceramic: This is the abrasive material with the highest longevity, sharpness, and aggressiveness. Its coarse grits enable it to handle heavy-duty metalwork, like removing substances on stainless steel.

4. Buffing pads & Polishing wheel

Buffing pads (or Polishing wheel) are made from premium wear-resistant wool. This attachment is used with an angle grinder for buffing and polishing various materials like metal, glass, wood, and ceramic.

To get the perfect finishing, you should use an angle grinder with variable speed settings.

5. Attachments for surface preparation

Surface preparation is a vital step in any mechanical project. You need a high-powered angle grinder and a suitable wheel (or an attachment) to handle this step.

There are two types of wheels for surface preparation:

- Non-woven abrasive wheel

This attachment is popular in the autobody industry or metal fabrication. The non-woven matrix design allows a small amount of air to get into and cool down the surface.

Thus, you can use this grinding wheel to remove harsh substances like sealers and adhesives at a high RPM without burning out the surfaces.

- Poly stripping wheel

This wheel is made from nylon and is often used to remove paint and expose the surface without harmful effects to the original surface.

6. Attachments for woodworking

If you want to use an angle grinder for woodworking, you must prepare these two essential attachments:

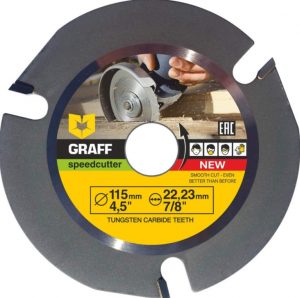

- Woodcutting disc

This round, flat disc has many hard tungsten carbide teeth to efficiently cut through softwoods and hardwoods. You can use this attachment to work on many types of wood, like cherry, walnut, pine, maple, oak, mahogany, etc.

- Wood carving disc

Unlike a wood cutting disc, a wood carving disc is mainly used for carving, grinding, and shaping wood. This donut-shaped disc also has hundreds of carbide teeth, but all the teeth cover the entire surface of the disc.

4 Amazing Attachments To Turn Angle Grinder Into Other Tools

1. Chainsaw Converter

Instead of purchasing an expensive chainsaw, you can use a chainsaw converter kit to turn your angle grinder into a portable chainsaw. A chainsaw converter kit often includes a chain guide plate, a quenching chain, an adjustable chain, a handle, a bracket, and a metal baffle.

This chainsaw converter attachment has some advantages.

- First, it is more affordable than buying a professional chainsaw for occasional use.

- Second, it is lighter, more portable, and generates less noise than a gasoline-powered chainsaw. It means that you can work for an extended period without tiring your arms and hands.

- Third, you can revert your angle grinder to its original appearance for its primary usage simply by removing converter components once the job is done.

Despite its awesomeness, this converter kit has some disadvantages. For example, this chainsaw-angle grinder tool or a general-purpose chainsaw is not designed for cutting metal. To cut metal, you should use a metal saw.

Plus, you have to check whether the sprocket fits the arbor hole on your angle grinder. Otherwise, you will end up wasting money on a useless kit.

2. Angle Grinder Belt Sander Attachment

You can use a simple homebrew attachment to turn your angle grinder into a belt sander to reach odd-shaped areas. This attachment is sticked with the grinder using clamps on the disc guard position.

The idler rollers on this attachment slide on a pneumatic spring to always keep the belts under tension. Depending on your demands, you can cut the belts to fit your needs.

The best part of using this attachment instead of purchasing a belt sander is that you don’t have to use any special machine tools. You don’t also have to spend extra money to get a belt sander. But a minor drawback of this grinder attachment is that you can hardly disassemble it from the angle grinder.

Read more about the difference between an angle grinder vs a sander here!

3. Wood Carving Chisel

You can turn your angle grinder into a chisel for wood carving, root carving, or bamboo carving with the help of a chisel set. Just install the attachment onto the motor shafts of your handheld tool to start your wood shaping projects.

Compared to traditional chisels, this attachment has some advantages.

- First, it comes with essential chisels for general-purpose woodworking.

- Second, it is easy to install and convenient to use, even for students or amateurs with little or no experience in this industry.

- Third, it is safe to use and won’t hurt your finger.

Are there any pitfalls of this attachment?

First, its performance depends on your angle grinder’s power. Thus, if you have a low-powered grinder, you can’t expect fast and efficient wood carving results.

Furthermore, this attachment is for general carving demands and can work on wood only. If you have any special requirements, you should choose a traditional chisel designed for those purposes.

For example, you should use a corner chisel to polish corners or a flooring chisel to repair or lift wooden floorings. To work on hard materials like stone, you should use a stone chisel with a wide, flat blade to break the stone.

4. Angle grinder drill chuck adapter

Need to make a hole on the wall to hang picture frames? You can attach a drill bit to your angle grinder with the help of a drill chuck adapter.

There are several benefits of this attachment. First, you can utilize your grinder as a portable drill or quickly change drill bits with the help of this small attachment. But the worst part of it is that you can’t use it to handle heavy-duty drilling purposes.

FAQs (Frequently Asked Questions)

1. Can you put a wood blade on an angle grinder?

The answer is YES. A wood blade, metal blade, or a blade made for cutting brick, etc, once installed, allows your angle grinder to do various tasks on different types of materials. For woodworking, you can either use a wood cutting disc or a wood carving disc to cut or shape your wood pieces.

2. Do all discs fit all angle grinders?

Although angle grinder discs are interchangeable, you must select the disc compatible with the tool. Always check the disc’s size and speed rating before installing it onto your grinder.

Never use the same disc on two angle grinders. Since its rotation center has been modified on its first grinder, reusing it on the second one will cause slight vibration on the first use and minor damages to your work. In addition, always check the disc before use to ensure that it is in good condition.

3. Can I use bigger discs on angle grinders?

You should not use a disc that exceeds your angle grinder’s supported disc size and speed limit. It is not only dangerous for you but also damages the tool.

Final Words

An angle grinder with a high RPM and a powerful motor is versatile for students, homeowners, and professionals. With the help of those popular angle grinder attachments, you can handle many tasks, like repairing metal furniture, cutting a ceramic tile, carving wood, or working on many projects without spending too much money on specialized tools.