If you undertake lots of DIY tasks, angle grinders are beneficial. Nevertheless, if the tool fails to function properly, its usefulness is thrown out the window. Knowing how to pinpoint and correct any flaws that occur to your power tool is consequently advantageous.

Therefore, common angle grinder problems, including both with the tool’s body and its blades, will be the focus of our article.

Contents

- 8 Common Angle Grinder Problems & How To Check

- 12 Common Problems With The Blades

- 1. The segments show excessive wear

- 2. The segments show uneven wear

- 3. The blade body shows uneven wear

- 4. The blade body shows bracks/cracks

- 5. Damaged bore

- 6. Outer wheel body is overheating

- 7. Tension is lost/Uneven rotation

- 8. The wheel doesn’t cut

- 9. Segments show cracks

- 10. The segment breaks off

- 11. The segment isn’t straight

- 12. Segments are glazed

- Safety Checklist Before Using Angle Grinders

- Make Sure It’s All Safe Before Working!

8 Common Angle Grinder Problems & How To Check

1. No power

If there are some problems with the power supply, your grinder won’t turn on.

Electric angle grinders get their power from either a mains supply or batteries. You should make sure that your tool’s batteries are in the right place and they haven’t died. And if it’s required, replace them.

If you’re using a corded angle grinder, ensure that its cord and plug are in good shape. If required, you should replace the fuse. Also, make sure there is enough gas, pneumatic grinders, as well as air for gas.

2. Slow speed

A grinder’s advantage comes both from the wheel surface and from its rotating speed. The grinder’s disc cannot reach its full potential in terms of performance, like running slow, if it gets so loose or stiff that it cannot spin properly.

Examine the connection between the nut and the disc’s center spindle. If it’s not tightly linked, tighten it using either a wrench or pliers. If necessary, clean the spindle’s components and lubricate it with a bit of lubricating oil to retain its movement.

3. Smoke from the grinder

You should be worried if your angle grinder is smoking. The problem can attribute to the disc getting clogged as a result of debris and rust accumulation.

If you observe smoke coming out of your power tool, turn it off and unplug it from the power source promptly. Detach the disc from its spindle to gain access to all components and clean them before attempting to use the tool again.

You must make sure that the wheel (both size and type) is appropriate for the job. Moreover, you should pay attention to an unusually high number of sparks, which can be indicative of a larger issue.

4. Motor gets hot

Like other electrical items, angle grinders produce heat when in use. But if its motor becomes overheating, it indicates one of the most common angle grinder problems. If the heat has developed after operating the power tool for an extended amount of time, switch it off and let it cool down.

Check the length of its cooling down period and whether it produces the same amount of heat after only a few minutes of use. Alternatively, inspect the tool’s motor to make sure that it isn’t defective.

5. Unusual noise

Every grinder produces a noise, however, there are instances when the power tool generates unusual or louder noise than ordinary at times. It could be a hint that your angle grinder has been overworked.

Ensure that the power supply to your power tool is sufficient and does not cause the device to struggle.

6. Cannot lock the spindle

If it’s impossible to lock the center spindle to switch the grinder’s disc, inspect the button, wrench, should pin, spring, cap, as well as other components. For instructions specific to your model, check the manual that comes with your angle grinder.

7. Motor works but the wheel doesn’t

If the grinder’s motor spins normally but its grinding disc doesn’t make the same synchronized movement, one of the following parts requires replacement: coupler, gears, spindle, or flange. For precise instructions applying to your tool model, consult the owner’s manual.

8. The blade wobbles

If the disc attached to your angle grinder wobbles, it might be difficult for you to operate properly. You’ll need to take care of this straight away. Start inspecting parts, including the grinding disc, flange, spindle, bearings, gears, and washers, make sure everything is in working order.

12 Common Problems With The Blades

Even if your grinder’s motor functions properly, you still cannot carry out your work to your liking if there are problems with its discs. Below are some of the most common issues that can occur, their causes, and general advice on how to solve them.

1. The segments show excessive wear

There are some causes leading to this problem. First, you may utilize an incorrect wheel for the material that is being cut. Another possible cause is the cutting speed setting is too low. Lastly, the cooling ability of the segments is inadequate.

Depending on the cause of the problem, either boost the spinning speed of the grinder’s disc or use a grinding wheel attachment made of a stronger metal bond.

2. The segments show uneven wear

The segment not wearing evenly can attribute to inappropriate use, inadequate cooling, or damaged machine shafts and bearings.

To fix and prevent repetitive problems, you should make sure that the disc is parallel to the cutting direction, raise the movement of air and water, and inspect the bearings on the shaft on which they are mounted for axial and radial clearance.

3. The blade body shows uneven wear

The wheel body can be worn unevenly because its RPM is inaccurate or its abrasive bits smalling into the material surfaces. In addition, inadequate cooling or choosing the wrong disc for your job also leads to the same issue.

We recommend that you change the rotating speed of the blade, raise its air or water flow, and alternatively switch to a more suited disc to your workpiece’s material.

4. The blade body shows bracks/cracks

This problem is caused by the blade being twisted excessively, inadequate cooling, or an overly strong impact at the beginning. Other possible reasons are too high RPM or storing the blade improperly.

For solving or preventing this issue, you should make sure that the cutting disk is parallel to the cutting direction, raise the movement of air and water, or decrease the rotational speed.

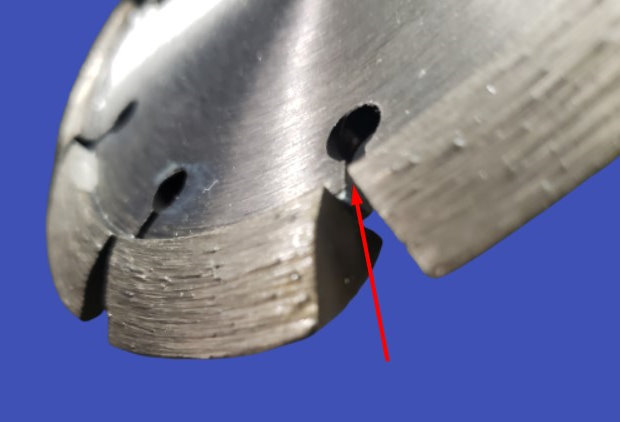

5. Damaged bore

Distorted bore can attribute to loose or dirty flanges. As a result, you should inspect whether the blade is securely attached to the power tool’s shaft as well as the condition of the flanges.

6. Outer wheel body is overheating

Twisting excessively or inadequate cooling can result in overheating the exterior wheel body.

It’s recommended that you make sure the cutting wheel is parallel to the cutting direction and raise the movement of air and water.

7. Tension is lost/Uneven rotation

The tension loss or uneven rotation of the grinder’s blade is caused by inaccurate wheel storage, inadequate cooling, or being twisted excessively.

Our advice is to guarantee that the disc is parallel to the cutting direction and increase the movement of air and water.

8. The wheel doesn’t cut

If your grinder’s disc is not capable of cutting, the material may be too hard for it or you set the RPM too high.

Therefore, you should either switch to a more appropriate disc for the workpiece’s material or decrease the disc’s rotating speed.

9. Segments show cracks

You may see some cracks on the segments, which can be caused by you choosing the wrong wheel for the job, setting too high RPM, or excessive pressure due to overheating.

The suggested solutions include replacing the grinder’s disc with one which is more appropriate for the material and reducing the rotating speed.

10. The segment breaks off

This issue can occur if the wheel has broken off during storage or shipment, been twisted excessively, incorrectly selected for the job, or the material moves during the cutting process.

You can avoid this problem by making sure that the disc is parallel to the cutting direction and reducing the pace and pressure of the feed.

11. The segment isn’t straight

A curved segment can be the result of the blade not being properly stored, transported, or used. Thus, you should keep it somewhere safe.

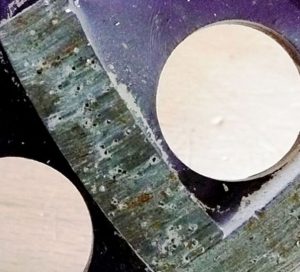

12. Segments are glazed

Segments are glazed because RPM is set too high, or the blade isn’t suitable for the workpiece’s material.

Reducing the wheels spinning speed or switching to a disk made for material that you’re cutting can help you avoid glazed segments.

Safety Checklist Before Using Angle Grinders

Angle grinders are dangerous power tools. Therefore, you should follow our safety checklist before using your power tool to avoid unfortunate injuries.

Measures for risk control

Some measures for risk control that you can take are:

- It is not permissible to remove the grinder’s guard. It should act as a barrier between the blade and the operator, covering at least half of the blade.

- Choose the suitable angle grinder disc for the job because an improperly selected disc can result in a shattering disc or a kickback possibly leading to the operator’s injuries.

- Make sure that other people are safely distant from your worksite.

- Your grinder should also be tested for electrical safety on a regular basis, and any technical problems are handled by a professional.

Before using the tool

Before putting your angle grinder in use, make sure that:

- Its handles and guard are secure.

- The blade is free of faults or damage.

- The utilized blade is suitably chosen for the ground or cut material.

- The flange and locking nut is suitable for the wheel in use.

When in use

When using your angle grinder, there are some precautions that you should take, including:

- Your task should be done with both hands.

- Before operating the grinder on the workpiece, let the power tool run to its operating speed.

- While holding your grinder against the material, apply light pressure to avoid the wheel grabbing and causing kickback.

- Have short breaks at intervals to relax your limbs.

- You must not put your grinder down till its blade has completely stopped working.

For a complete list, please refer to this link.

Make Sure It’s All Safe Before Working!

Common angle grinder problems can arise regardless of the type or condition of your power tool. Our article has helped you know how to detect these common problems and their sources as well as how to prevent them from happening or reoccurring. This is crucial know-how in order to guarantee both your safety and your tool’s longevity.

I have one of your large angle grinders, my problem is that I am experiencing difficulty switching it off!!

regards Graham Smith